March 11, 2025- Worried about renewed inflation and new tariffs? Here are actionable steps supply chain leaders can take. It is understandable that when you add renewed worries about inflation, a recession, and now tariffs all adding to the cost of healthcare goods and services, you get a pretty bleak picture. As a number of organizations including GPOs and others said, now is the time for preplanning.

Consider the following:

75% The number of medical devices purchased in the United States that could be impacted by tariffs because they are manufactured oversees.

On the pharmacy front, about 80 percent of Active Pharmaceutical Ingredients (APIs) come from oversees—and growing. For example, China had 219 API facilities in 2023, versus 134 in 2021.

| U.S. Medical Device Market 2023 | $197.8B |

| Projected U.S. Medical Device Market 2033 | $305.1B |

All of this is consequential because the U.S. medical device market is expected to continue to grow quickly. Beyond the solutions I have seen to date, here are a few more.

First, ask questions and be an active listener

Some companies have already announced that they cannot fully absorb the cost of tariffs. While this should be considered, there is confusion about what products are actually covered, how much the tariff actually is, the effective date, and other key details. When examining large volume purchases, a key can be working with your supplier and understanding these and other details. If they cannot absorb the full amount of the tariff, can they swallow part of it—and how much? This is an area for inquiry and negotiation.

Inflation is another worry. As you look back into your supplier’s supply chains, the question I like to raise is: what, when, and how much of a price increase was taken by the supplier from their suppliers for the products in question. Asking them to provde those increases to you in a nice way may create an opportunity for reaching a compromise around inflationary price increases. Again, this is an area for inquiry and negotiation.

Be sensible

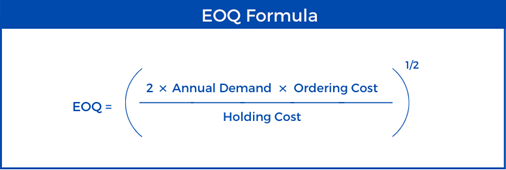

Many suggestions include something like making bulk purchases well in advance of the issues. Buying large quantities of products in bulk may seem like a solid solution to retain lower cost inventory for a longer period of time. However, there is a break-even point financially and it can be calculated by using an Economic Order Calculator. Sure, they have been around for a long time but they still work and can also avoid issues down the road.

Finally, consider onshoring

One of the major complaints about onshoring has been the increased unit cost. It probably does cost somewhat more, but is the total increased cost of the purchase less than the total holding cost? If the answer is yes, dig deeper and consider some other advantages.

- A shorter supply chain yielding reduced delivery charges

- Avoids the total cost of over-buying products in bulk

- Can improve product quality

By supporting on shore suppliers, you can add to their volume and help them reduce the cost of their own raw materials, thereby lowering the price.

By John Strong, Co-founder & Chief Consulting Officer, Access Strategy Partners Inc